Maquina de costura.

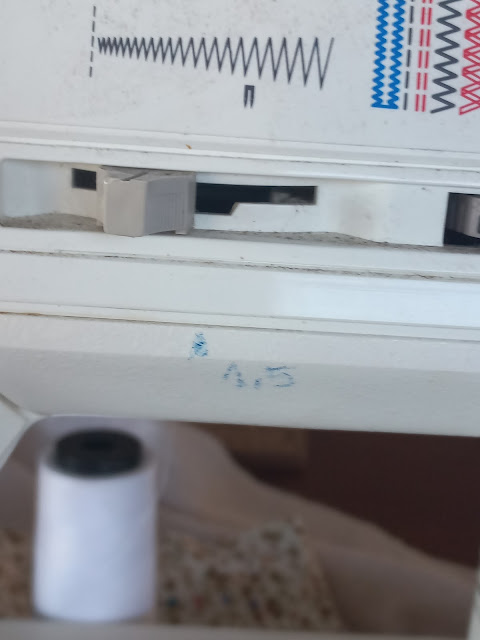

This is the foot to make the holes of the buttons to blouses, and I measure by these two guide lines:

Measuring the distance:

I measure and the distance from the place of the hole is that cleft thatalready have in the sewing machine.

Measuring the size:

And the other guide fir the size of the buttons that I choice for that blouse is that mark in the foot to make buttonsholdes. I put an adesive and write to I remember each is where I gonna stop.

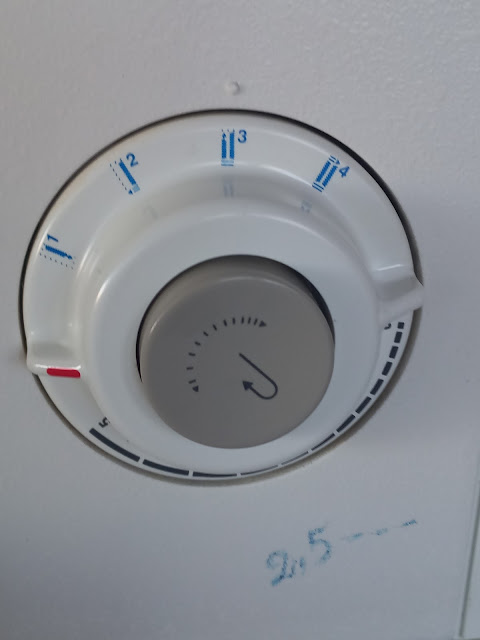

And that machine have that ease, the phases of the button hole are in those presets on the dial of the sewing machine.

And this phot is one freebies, my mother had a friend that keep his marks noted in a book, I write in the machine with an pencil, that is the measure for the zigue-zague, with the note of the size of the stich in th edial.

This is the foot presser to fix the buttons in the cloth.

And this is how to regulate the machine, in the dial put the distance of the stiches to zero.

Part of the freebies that 2,5 is the label that I made in the iron of the machine to say the padron of my clothes for straight sew.

measuring the distance between the holes of the button:

And with the button in the place in the sewing machine you gonna regulate, manually, in the handle of the machine and not in th pedal, in that regulation, with all the care, andusing the handle manually, and not with the pedal, if the buttons are the same you gonna regulate once for all, but to fix buttons have to have that care, so you place the button in the place hold it with the foot presser, and see every sinlge time in the beggining if the neddle will got in the pair of holes, if right for the right and left hole, you can know turn the machine, and also when fixing buttons is very important the foot presser and neddle be good screw, or the neddle gonna hit the button, and break or button or neddle or both.

Rute Bezerra de Menezes Gondim

No comments:

Post a Comment